The weekend of Oct 4 we pressed some cider, poured some concrete, and made a bird feeder.

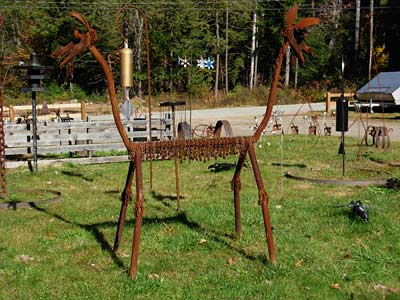

On Saturday morning we went to a big flea market at Stonehedge, an outdoor music venue between Gray and Windham. Arlene had seen an ad in a local paper a couple of weeks before. We had been expecting to go to it the weekend before, but it had been postponed because of the rain. We were glad to have found where Stonehedge was, but the sale itself was disappointing. We bought a lot of books at one booth, but there wasn’t much else interesting.

We stopped at the hardware store in Gray and got a couple of bags of concrete mix so I could level out the base for the fire pit. The bags were pretty flat and hard. The guy who brought them out to the car said that they had been compressed from being on the bottom of the pallet but would be OK once I opened them.

We came home via the Shaker Village, which was having a cider making demonstration. The information we had on the event said, “bring your own apples or buy Shaker apples.” We had brought 2/3 of a basket of apples, mostly drops from the baldwin tree. There was one group ahead of us, so we got to see the process once through before we started.

The first step was to grind up the apples in an antique mill with a big crank which turned two wooden rollers about the size of big rolling pins with gear teeth running the length of the rollers. There were iron gears on the outside of the mill so the rollers weren’t really turning each other, just chewing up the apples. With enough cranking and some help from the guys running the demonstration, who had a big wooden pestle to push the apples down between the rollers, I ground up the apples.

Then the apple chunks went into the cider press. If you haven’t ever seen a cider press, start by getting the size — a little smaller than a five-gallon plastic pail, with straight, parallel sides. Now make it out of vertical wood strips instead of plastic, with a couple of iron bands around it to hold it together. Now make the wood strips half as wide, so there’s space between them for the cider to drain through. Put some a sturdy frame around it, and a crank on top with a threaded shaft so you can put a heavy wooden disk on top of the apple pulp and force it down as you turn the crank. The apple chunks are in a plastic mesh bag (obviously not how it was done 100 years ago. I wonder if there was a canvas bag in the picture?) inside the press, and the whole thing was on a plastic tray that normally lived under a dish drain, draining into a bucket. We had enough apples to just about fill up the press. You have to be careful not to turn the press too fast at the beginning, or the cider comes out so fast that it runs over the sides of the dishpan drain instead of going into the bucket. At the end of the pressing there’s no question of going too fast; you’re really working hard to press out the last of the cider. The people running the demonstration had a supply of plastic jugs and caps for them. They funnelled the cider into two half-gallon jugs (one was only 1/3 full. A full basket of apples would have made two full half-gallons) and capped them. We had to pay for the jugs, but the cider was all ours. The cider looked very official when it was finished, with the kind of caps that you get in a store that need to be broken to be opened, and tasted very apple-y.

I wanted to get going on the concrete right after getting home, lest the weather interfere. I cut up one rough-cut pine board from Red Mill into foot-long pieces and set them around the outside of the fire pit foundation to serve as a form, trying to get them level with the high point on the far side of the foundation. The bag of premixed concrete that looked worse compressed was almost useless — it wasn’t just compressed, it had hardened into concrete in the bag. That will happen to concrete mix that’s been exposed to humidity for too long. It wasn’t just that it didn’t pour. When I put it in a wheelbarrow and worked it over with a sledgehammer, it didn’t turn back into powder, it eventually broke into chunks of concrete. And I didn’t just give it a couple of taps with the sledgehammer, I worked it over the way you might pound a steak with a meat tenderizing mallet. The second bag was not quite so bad, but I think there was less than 2/3 of a bag of useful mix between the two bags. We still had a full bag from the nine that Matt and I had bought two weeks earlier, so I was able to mix up enough concrete to get the foundation close to level.

Sunday we went to the dump and the bulky waste area to try to get rid of the extra concrete chunks. Bulky waste wouldn’t take the concrete, but we did pick up some more scrap wood and a couple of long (four feet by six inches) strips of plastic tile surfaced masonite. It looked like just the thing to make a circular form for the inside of the fire pit foundation, which wasn’t yet as smooth and level as I would have liked. Then we went to the hardware store in Naples and got a sack of premixed sand and topping concrete. I put the masonite strips in place, got the top level with the high spot of the foundation, mixed up the sand mix, and ended up with a nice smooth reasonable level pad.

The big bird feeder that stands on a pole in the yard had fallen apart late last winter. Matt had made a temporary repair, but the wood was pretty rotten. Between some scrap wood, some wood salvaged from bulky waste, and the plexiglas and the hinges from the old feeder, I made a duplicate feeder and put it up. The crosscut sled my father had made for his table saw was essential for cutting the angles for the roof and kerfs to hold the plexiglas.