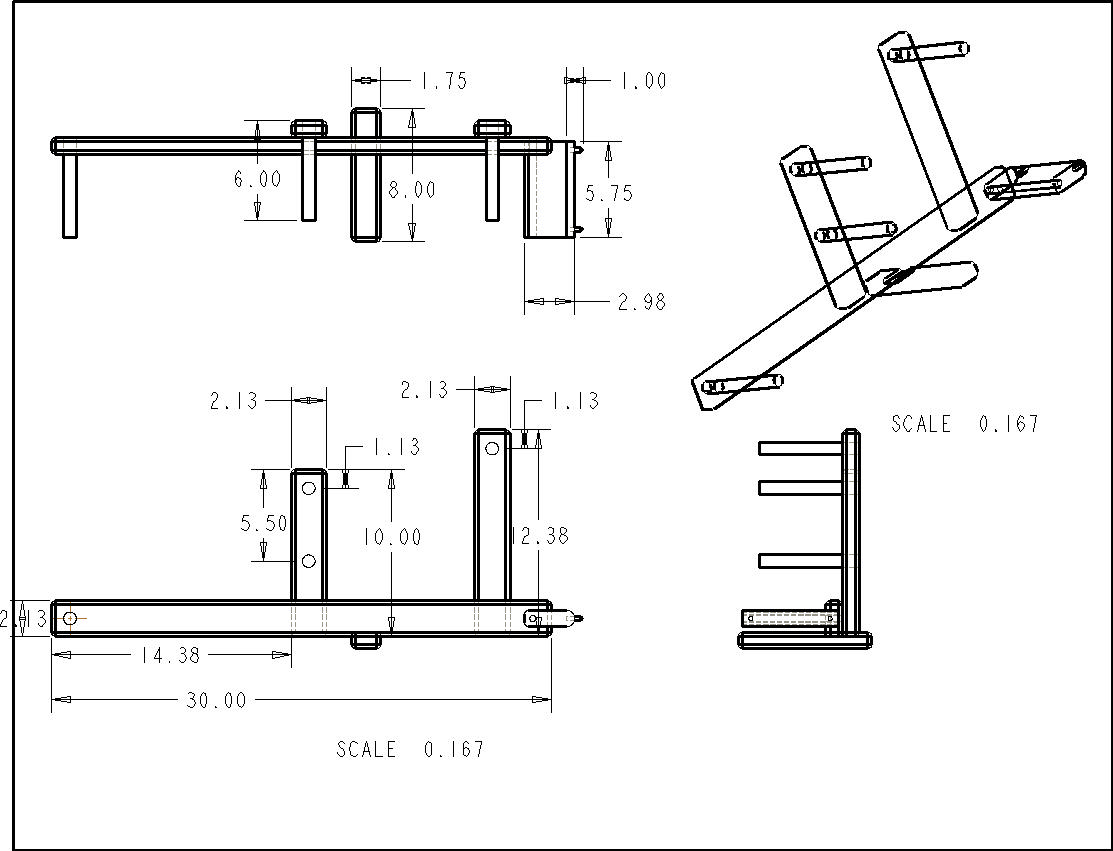

Someone left a comment recently asking if I had a plan for an inkle loom. I didn’t then, but I do now.

An inkle loom is good for weaving narrow pieces of fabric up to about four feet long, or longer if you build it with more zigzags than the one in this plan — I mean more dowels sticking out from the uprights for the warp to zigzag between. Anyway, one like this is good for weaving belts, guitar straps, handbag straps, decorative trim for clothing, etc.

Recommended material for this one is fir porch stepping, nominal 5/4 inch thick (tell the people at the lumber yard “five quarter fir porch stepping”) cut to about 2 1/4 inches wide, edges rounded off.

The plan came out with dimensions in decimals of an inch. By no means does it need to be precise! Think of all the “.38” as 3/8 inch converted to a decimal and rounded off; likewise all the “.13” are 1/8 inch. If your lengths are within a quarter inch of those given it’ll still work fine.

The hardest part of this plan is boring a hole straight through the tension block. If you have a drill press, it’ll work. Otherwise, good luck coming out anywhere near the middle of the block on the far end. I used to use a big long 3/8 inch carriage bolt as the axle for the tension block, with a big wing nut and washer to hold it on. Number 10 or 12 by 1 3/4 inch flat head wood screws are good for holding the parts together.

OK, here’s the plan. Write or comment with questions, and I’ll add more comments or edit this post to answer them. Or if this isn’t clear, I can make drawings of the individual parts. Probably if you want to make a loom from this drawing, you should save the .jpg separately so you can view it full size.

In looking your drawing of the inkle loom, I would like to ask a couple of questions. Is that 8 inch piece on the bottom a stand to support the loom or something else (it does not appear to be flush with the bottom). Also, would you be able to provide a detail drawing of the tension mechanism?

Thank you in advance,

Nelson